When it comes to Roller coaster wheels, safety, reliability and wear resistance are key which is why they are engineered to exacting standards. The same rules apply for any wheel design, but none more so than in the amusement park industry!

Key Areas to Consider

A roller coaster’s wheels may actually be one of the biggest limiting factors of building ever taller and faster rides. To design the perfect wheel for a high-speed roller coaster, engineers must find the best combination of these four main requirements.

1 – Low Rolling Resistance

Friction causes the roller coaster train to slow down, rides are designed for speed so wheels require minimal friction.

2 – High Load Endurance

The wheels on a roller coaster train need to be sufficient to carry the weight of the passengers and the vehicles. They also need to be able to operate under forces of up to six times that of gravity.

3 – Smooth Ride Performance

Wheels need to be able to absorb impact on uneven surfaces due to minor imperfections or debris on the track.

4 – High Durability

In order to help minimise downtime and reduce maintenance costs, the wheels on a roller coaster train need to be highly durable.

What Types of Wheels are Used on a Roller Coaster Train?

There are a number of different wheels found on a roller coaster.

The main wheels used to keep the train securely on the track are:

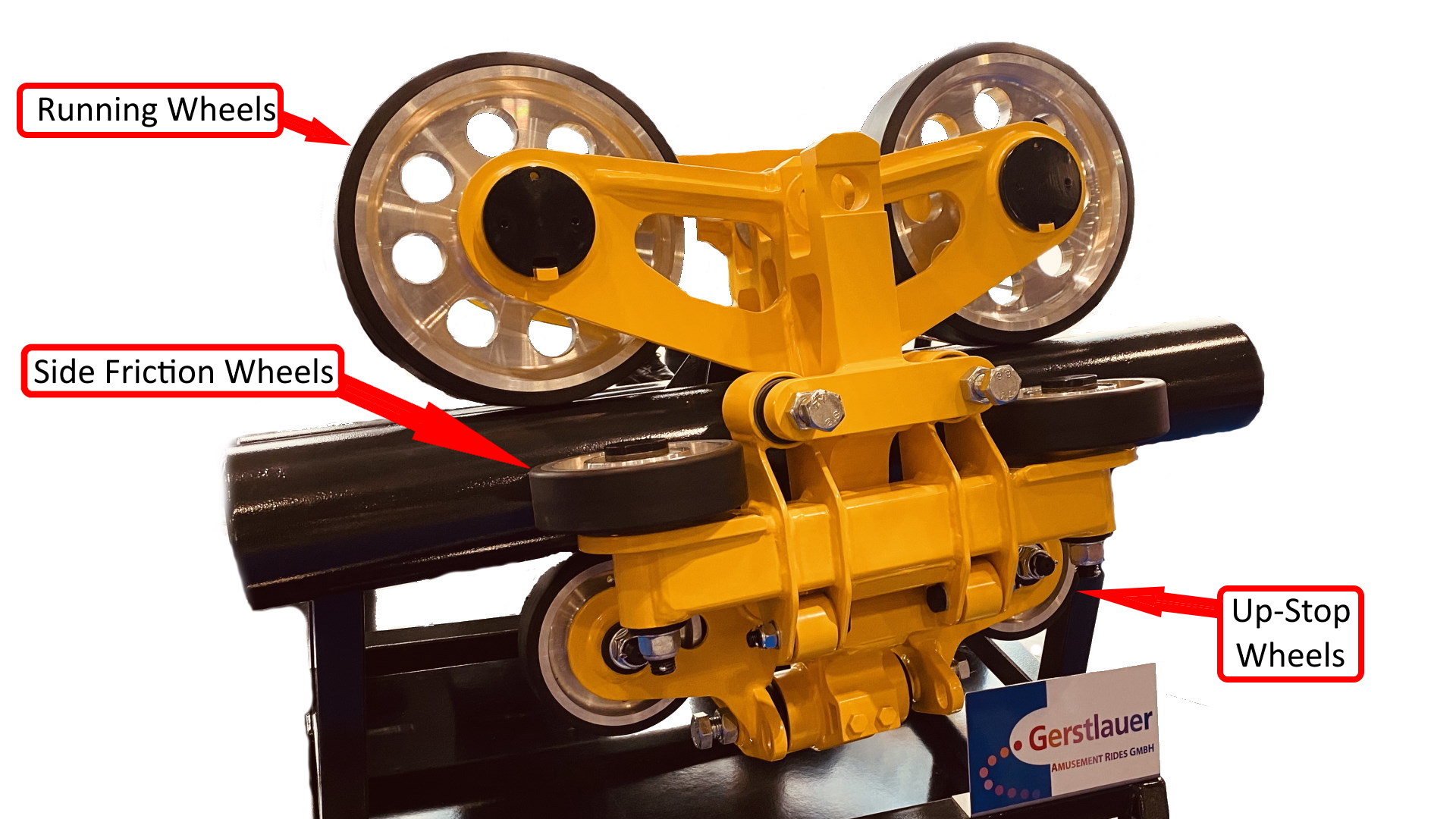

Running Wheels

The most obvious set of wheels on a roller coaster are the running wheels which provide the connection between the train and the roller coaster track. These load-bearing wheels take the weight of the passengers and the roller coaster train. They can also be referred to as Road wheels and Tractor wheels. Running wheels may lift off the track when the vertical g-force is zero or negative, but the up-stop wheels prevent the train from coming off the rails.

Side Friction Wheels

Depending on the roller coaster manufacturer, side friction wheels are mounted on either the inside or outside of the roller coaster track, perpendicular to the running wheels. Side friction wheels hug the sides of the rails, keeping the train in the centre of the track, and helping to prevent the roller coaster train from derailing.

Up-stop Wheels

Positioned beneath the roller coaster track, all modern roller coasters have up-stop wheels to prevent the train from lifting up off the track. They can also be referred to as underfriction wheels and up-lift wheels.

What are Friction Wheels?

You may have also heard people talk about Friction Wheels. These are located on the roller coaster track and not on the train, their purpose is to propel the roller coaster train along a piece of track, they are also referred to as drive tyres or kicker wheels. They are often used in station areas and brake runs, but they can also be used to propel the rollercoaster train up a lift hill.

Click Here to learn more about friction wheels.

Materials used to Manufacture the Wheels

Roller Coaster wheels can be manufactured from either nylon or polyurethane, both materials are suitable for the intended application with each having its advantages and disadvantages. Many amusement parks will use a mix of both nylon and polyurethane wheels to achieve optimal ride performance. Roller coaster wheels supplied by TEP Technica typically come with a Vulkollan or polyurethane tread directly bonded to a steel or cast iron centre. The wheel assembly is then connected to the axle through a bearing. Important characteristics for roller coaster wheels include safety, durability, reliability and low replacement costs.

Nylon Wheels

Nylon is a hard plastic which offers low rolling resistance, and durability meaning lower maintenance costs on the wheels but nylon wheels are potentially more demanding on the track. Hard plastics do not provide the smoothest of rides and passengers will encounter vibrations.

Polyurethane Wheels

Polyurethane is a softer plastic than Nylon, providing a smoother ride for passengers with less vibration. The softer tread also means a slower ride as friction is increased.

Where can you buy Roller Coaster Wheels?

TEP Technica can supply any wheel to any specification which means they can offer wheels for roller coasters, fairground rides and almost any amusement park ride in operation today. TEP Technica supply Vulkollan, polyurethane and rubber load and guide wheels for slow-moving rides with low requirements right through to the super-fast roller coasters that require very high quality and high load capacity wheels which can operate at maximum efficiency for long periods of time.